Our ESG Indicators

Aperam’s mission is to produce superior products in a sustainable and responsible way, which is why the principles of Environment – Social – Governance, or ESG, have always been at the heart of our strategy.

Raising the Bar in Environmental Excellence

When it comes to the environment, simply complying with regulations is not enough – we aim to exceed. That’s why we redefined our targets, adopting a 2030 deadline for reducing our CO2 footprint, energy use, water consumption and air emissions even further. We are also committed to achieving carbon neutrality by 2050.

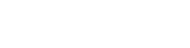

CO2

Since 2017, our CO2 footprint intensity has been consistently well below the industry average of 0.83 tCO2e/tcs (World Stainless). Today, our (scope 1+2) footprint is best-in-class, at 0.28 tCO2e/tcs – meaning Aperam has already achieved its CO2e 2030 objective of -30% vs. 2015. The company will soon disclose new objectives according to our Science-Based Target Initiative (SBTi) submitted roadmap.

In terms of scope 3 emissions, in 2023 we reported a global scope 3a of 3.59 MtCO2e/ton, of which scope 3.1 is 3.13 MtCO2e. Our scope 3b is much less at 172 ktCO2 e/ton, while our global scope 3a intensity is 1.49 tCO2e/ton. Without sequestration, Aperam’s global footprint (scope 1+2+3a) is 1.9 tCO2e/tcs. With sequestration, it stands at 1.7 tCO2e/tcs.

About CO2

Aperam monitors its Scope 1, 2 and 3 emissions. Scope 1 covers direct emissions from owned or controlled sources. Scope 2 covers indirect emissions from the generation of purchased electricity, steam, heating and cooling consumed by the reporting company. Scope 3 includes all other indirect emissions that occur in a company’s value chain, with the bulk of it being related to extractive raw materials such as Nickel and Chromium in the stainless and alloys sector.

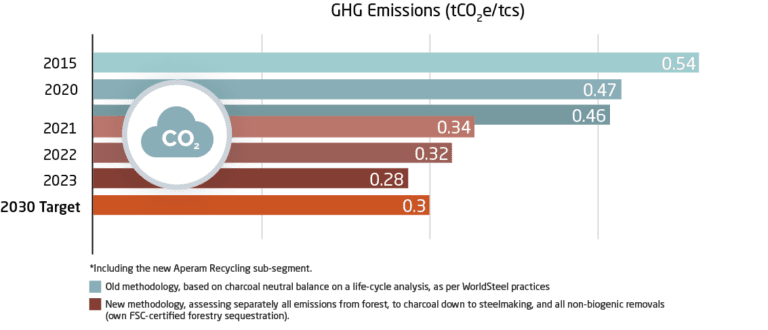

Energy

Aperam’s energy mix remains a subject of pride, with 39% coming from renewable charcoal biomass. In fact, renewables now account for 52% of our total energy use which, in 2023 was 13.8 GJ/tcs or 3.8 MWh/tcs2. As for electricity, in 2023, our global carbon footprint decreased in our main countries of operation. In addition to lowering the emission factor of our electricity suppliers, several other actions have had a positive effect, meaning we remain on track to achieve our target of an 11% reduction in

energy use by 2030.

About Energy

Aperam is making moves to increase our use of renewable energy, including the installation of solar panels at several of our plants. For example, the 50,000 panels installed at our Genk facility now produce nearly 20 GWh of power every year, covering almost 5% of the site’s electricity needs. Likewise, the 15,000 panels installed at our Châtelet plant have an installed capacity of 6.0 MWp and an expected annual production of 6,300 MWh of green electricity.

In 2023, our Isbergues site began an initiative to recover waste heat and improve the reliability of its cooling towers – actions that are expected to save up to 128 MWh in electricity and 4106 MWh in natural gas per year.

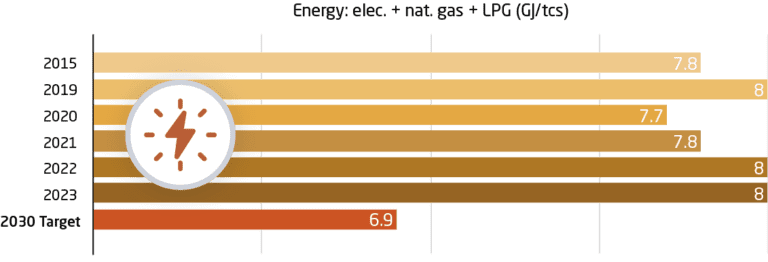

Dust & Air Emissions

Having achieved our goal of a 40% reduction in ducted dust emission intensity in 2021 (compared to 2015), in 2020 we announced a new target of a -70% decrease and a commitment to reducing diffused (non-ducted) dust. To achieve this, we periodically measure diffused dust to evaluate leakages and identify areas for improvement. We also implemented dust emission improvement plans that focus on either containing, ducting or collecting the dust (in Europe, the collected dust is sent to our Recycling and Renewables Division for recycling). Thanks to efforts like these, in 2023, our total Group emissions was 111 g/tcs.

About Dust & Air Emissions

Local air quality is an important issue for our operations. Our Environmental Policy commits us to a long-term approach to environmental performance and, according to our stakeholder engagement, dust (particulate matter) stands amongst our most important material issues. In addition to dust, we also produce other air emissions, in particular NOx and SOx. Because this issue is so important to the local communities we work in, Aperam has committed to going beyond what is required by current regulations.

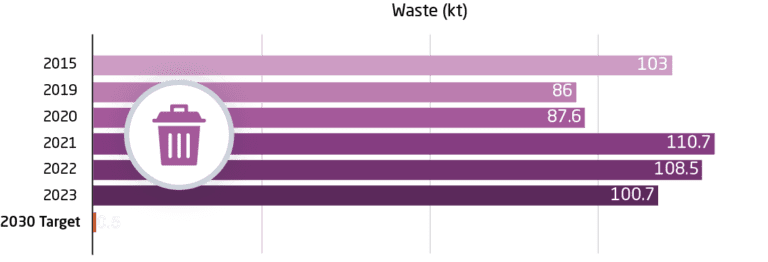

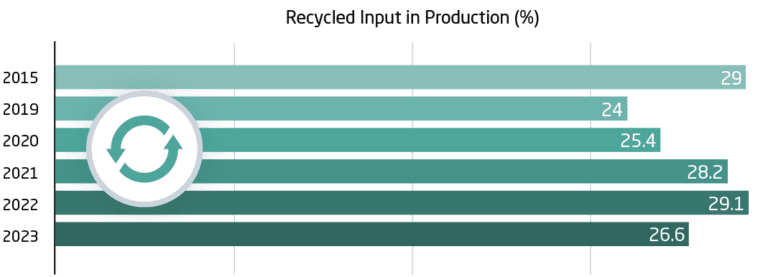

Waste and recycling

In 2023, just 6.9% of our by-products were sent to the landfill. The remainder (93.1%) is either reused, recycled or stored for future recycling. Our waste recovery ratio stands at 93.1%, with 29% of all our material now coming from recycled sources – including scrap. On average, Aperam’s products, including those made in Brazil (where the scrap market is nearly nonexistent) contain 65% metallic scrap. At our European sites, that figure is 88.5%, with some of our austenitics produced at the Genk facility recording scrap rates of over 95%.

About Waste & Recycling

Stainless steel is, by its very nature, sustainable. That’s because stainless steel is long lasting and infinitely recyclable without any loss of properties – and can use recycled scrap as a raw material. In fact, our European production processes use about 90% scrap metal, Our acquisition of ELG, a global leader in collecting, trading, processing and recycling stainless steel scrap and high-performance alloys, which has been fully incorporated into our Recycling and Renewables division, is accelerating our roadmap to become a zero-waste (for landfill) company.

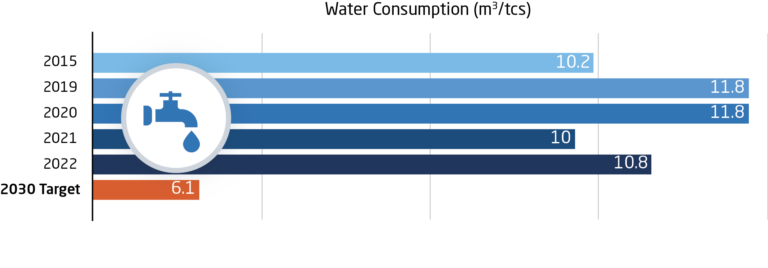

Water Intake

With the aim of reducing water consumption by 40% by 2030 (over 2015 rate), we routinely monitor our water intake. We also continue to increase the amount of recycled water we use, which is currently at 97.8%. Of the 4% of water that we do extract, 79% comes from rivers and 9% from collected rain. Most of the water (66% in 2023) we do withdraw is returned to the river after treatment.

Water Quality

We also monitor the quality of the water we discharge into rivers to ensure it complies with our permits in terms of volumes, pH, temperature, particles of suspended solids, and metals in water. In 2023, we reported a total water discharge of 13.1 million m3 -20.3% from 2012), including 5.204 kg/tcs of metal discharge (+44%% from 2022) and 81.711 g/tcs of suspended solids (-29% from 2022).

The Health & Safety of Our People is our Top Priority

As a core value, health and safety guides all our actions. It also has the power to stop any operation or decision. So, while we continue to work on programs to improve the safety, health and well-being of our employees, we also dedicate a lot of energy toward employee development.

Health & Safety

Aperam’s corporate health and safety standards help prevent workplace accidents and fatalities. As these standards are only effective when properly implemented, we established our Fatality Prevention Standards (FPS) and Fatality Prevention Audit (FPA) as measures for ensuring compliance. On top of our continuous monitoring with leading and lagging indicators, our people are actively involved in the design and implementation of our H&S program. We also gather feedback from all employees via our Global Employee Climate Survey.

About H&S

Simply put, a safety culture is “the way we do things around here.” We review safety research, learn lessons from incidents in our industry, and consult with our people to develop a framework that defines the critical behaviors that characterize a robust safety culture. This framework helps everyone at Aperam understand the behaviors they should and should not display to play their part in strengthening our safety culture.

Biodiversity

In response to growing concerns of our stakeholders, Aperam has established biodiversity plans at each

of our main plants. Based on the Global Reporting Initiative and the ResponsibleSteel frameworks, our

plans involve a preliminary identification of local, vulnerable or invasive species, their natural habitats

and of any possible disturbances that changes in our operations could cause. In 2022, we added new

indicators on biodiversity to our dashboard, letting us track our progress.

Botanickel

Aperam, together with Econick, a spin-off of France’s University of Lorraine that specializes in the phytoextraction sciences, have formed a new joint venture. Called Botanickel, the company seeks to become a world leader in the responsible and sustainable production of biosourced nickel for the stainless steel industry.

Diversity

Since 2018, we have implemented a program inspired by the United Nations’ Women Empowerment Principles to increase female representation at all levels of the Aperam community and to ensure our work environment allows them to thrive and demonstrate the very best of their talents. As a direct result of this initiative, we have already seen a very tangible increase in the number of women working at Aperam – accounting for 16.2% of our employees (2023). In 2022, Aperam decided to expand its diversity program to include all kinds of diversity- not just gender.

About Diversity

Because Aperam sees value in a diverse workforce, we are keen to attract the very best talent, regardless of age, gender, national origin or disabilities and integrate everyone into the Aperam family. We are committed to providing an inclusive work environment and equal opportunities to all.